In this guide, we are going to show you how to remove “push-fit” pipe connections.

These kinds of fittings connect pipes together by “clawing onto” them and creating a watertight seal.

As a result, you will not be able to unscrew “push-fit” fittings. If you do attempt to loosen these connections with a wrench, they will continue to rotate until your hands get tired.

Trust me. I’ve been there.

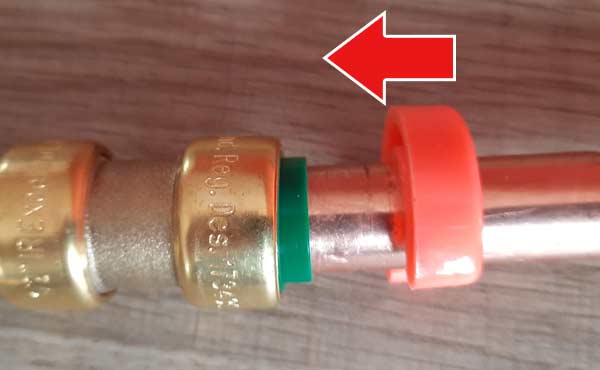

An example of a brass push-fit fitting. As you can see, this brass connector has a green plastic part on either side of it.

The fact that you cannot unscrew these fittings can be confusing to DIY plumbers.

In the photograph above, you can see an old brass push-fit fitting that connects two copper pipes together. You can also see by the marks that someone has attempted to loosen this fitting by using a wrench.

However, this will not work as there is a “claw” inside the connection that will not let the pipe go.

It is worth noting that these fittings can also come in the shape of “elbows” or “bends”.

An example of a brass “elbow” from Pro Plumb. Other popular brands include the likes of Tectite and Shark Bite.

How to remove brass push-fit fittings.

To remove these kinds of fittings, you will need to push in on the plastic part and then pull the pipe out.

This plastic part can be any color. In the examples above, you can see that the plastic part of the connection is green.

Although it is possible to push in on this plastic by using your hands, doing so can be pretty difficult and sore on your fingers.

The best tool to use is a push-fit “demounting” tool. More often than not, this tool will look like a horse shoe.

You can usually find this kind of demounting tool in any hardware store that sells plumbing fixtures.

Note that the demounting tool in your local hardware store might not look exactly the same as the one above. For example, some of them will be longer and others will have a notch or a grip at the top.

How to use a push-fit demounting tool.

Unfortunately, the instructions on the back of some of these tools can be frustratingly bad.

In fact, you might even discover that there are no instructions at all.

To use the demounting tool, simply push it onto the pipe like this:

The demounting tool should wrap around the pipe.

In the image above, you can see that I have forced the tool onto the copper pipe. Now, in order to loosen the fitting, I will need to push it towards the plastic part.

If everything goes according to plan, then the plastic section on the connector will compress inward and release the copper pipe. At that stage, I will be able to pull the pipe out.

Using an adjustable wrench or a ring spanner.

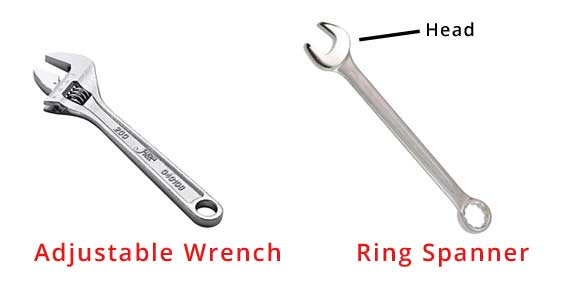

You can also try to use an adjustable wrench to do this job.

As the name suggests, an adjustable wrench (or spanner) is a wrench that allows you to adjust the size of its “jaw”.

This will allow you to tighten the wrench around the pipe until it fits.

Note that it should only loosely fit the pipe. In other words, do not tighten the wrench so hard that it scrapes along the pipe.

Once the wrench is in place, you can push it towards the release mechanism on the fitting.

The difference between an adjustable spanner and a ring spanner.

It is worth pointing out that you can also do this with the head of a ring spanner. However, the ring spanner will need to be the correct size.